A range of automatic pallet labellers built specifically to maintain high reliability in warehouse and end-of-line packaging applications – reducing the need for human intervention, often by fork truck drivers – is being demonstrated at IMHX for the first time by Logopak International.

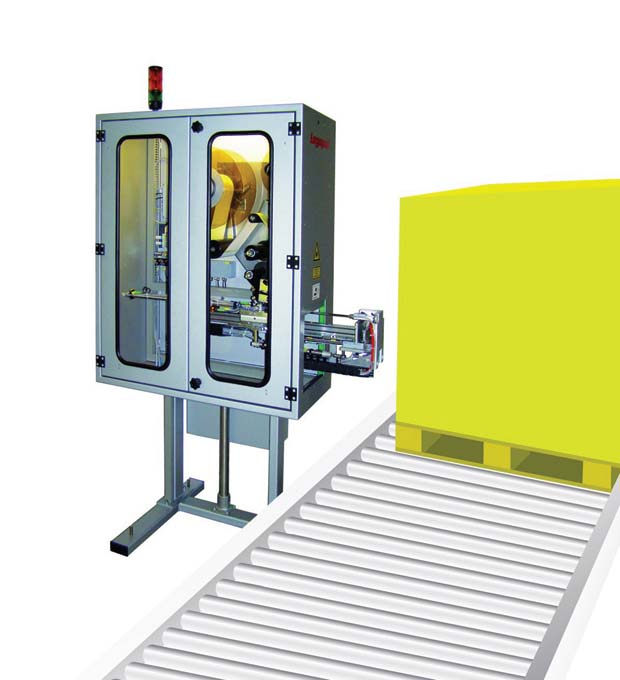

The 815 series print & apply machines are housed in a purpose designed steel enclosure – with trap doors for the applicator arms – protecting the print heads against airborne dirt or dust. Bar codes are checked for legibility as they are applied, and automatically reprinted if necessary.

The 815 series print & apply machines are housed in a purpose designed steel enclosure – with trap doors for the applicator arms – protecting the print heads against airborne dirt or dust. Bar codes are checked for legibility as they are applied, and automatically reprinted if necessary.

“Automatic pallet labelling eliminates the increasing amount of time lost as fork truck drivers mount and dismount to print and apply a label by hand, as well as ensuring accuracy of label data and label positioning,” points out Logopak sales director Howard Jagger.

“However, with their industrial quality enclosures, the Logopak machines also reduce substantially the risk of time lost by drivers in resetting machines after a stoppage following poor print quality caused by dust from warehouse traffic.”

Capable of 100 pallets an hour, the compact Logopak 815 machines provide a comfortable operating margin over the 60-80 pallets an hour requirement of most production lines.

Logopak International Limited

Tel: 01904 692333

Email: info@logopak.net

1 Comment

When using machines to run your warehouse, maintenance is of vital importance. For without maintenance, machines would not be able to function properly nor would it last long.